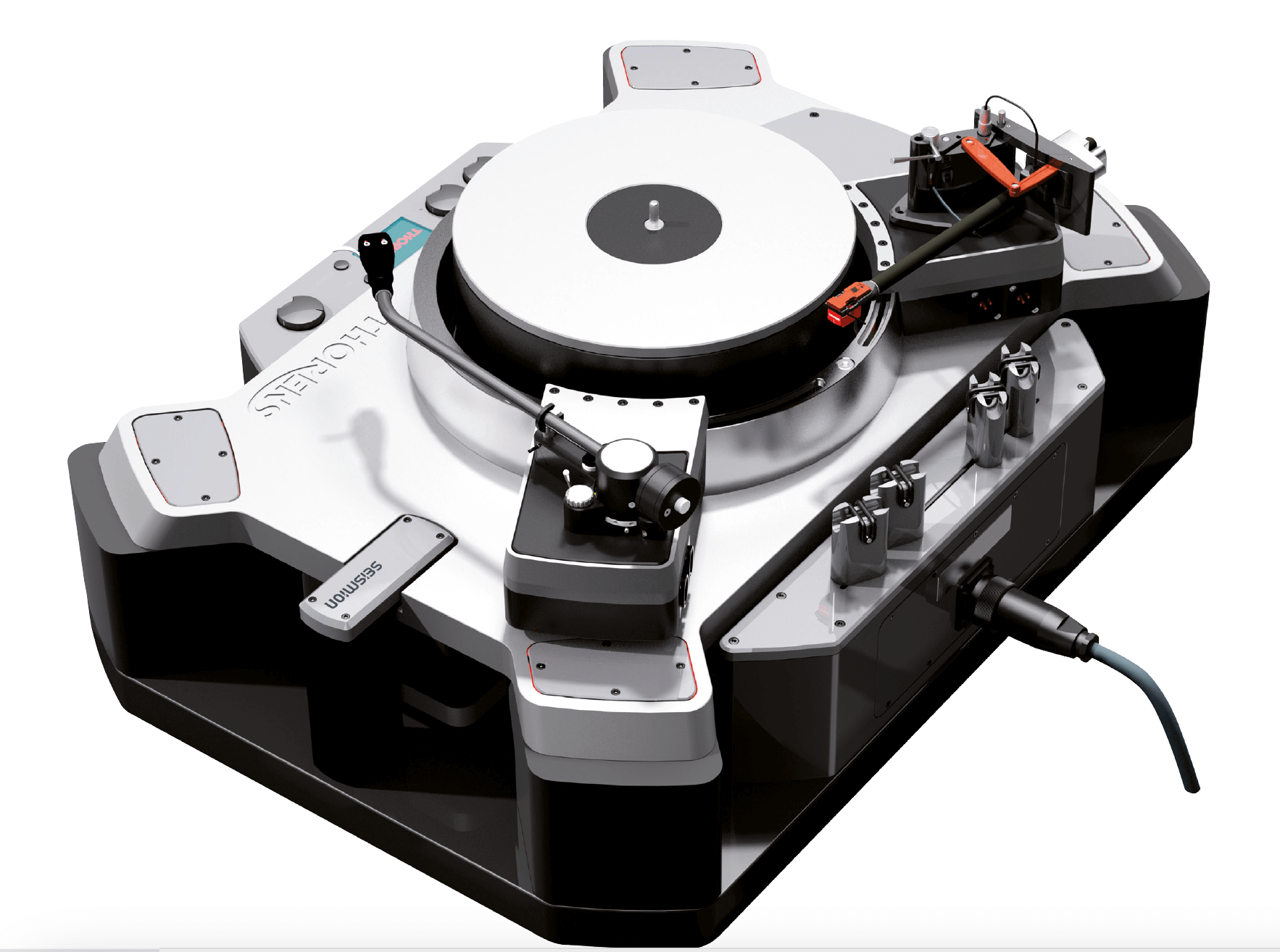

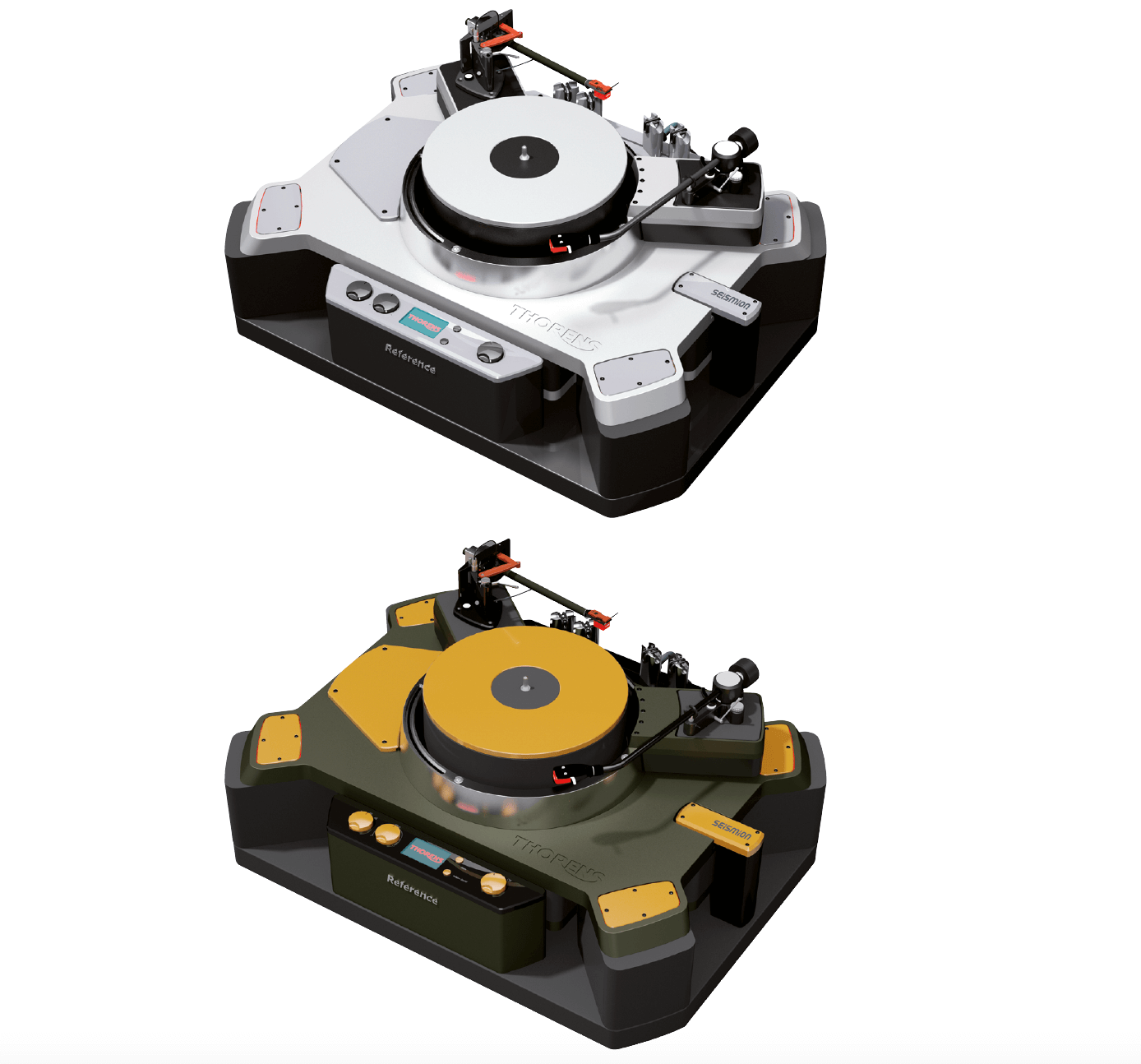

“We are very proud to present this worldwide innovation to celebrate the 140th anniverivery of Thorens” stated Thorens owner and managing Director, Gunter Kürten. “The Thorens New reference turntable will be available in limited numbers beginning early in the last quarter of the year with a price of $355,000 CDN including the stand and two tonearms. Those interested are highly encouraged to join the waitlist.”

Like all turntables, the electrical signals in the turntable are created by stylus mechanical vibrations as it moves along the grooves of a vinyl. These vibrations are converted to sound. The problem of course is that environmental elements such as people walking in a room also cause vibrations that can be picked up by the stylus. Even self-generated vibrations from the turntable itself can cause unwanted distortion and noise and it is not possible for a stylus to determine the difference between actual music vibrations and parasitic disturbances.

The Thorens design team led by Helmet Thiele, collaborated with the German company Seismion, an internationally renowned manufacturer of active vibration isolators to design and reimagine the isolation features of a turntable. Seismion used their expertise in active isolation systems in the semiconductor industry to create a vibration isolation never seen in a turntable, based on piezoelectric acceleration sensors with an extremely high sensitivity, and an all-linear electronics control circuit to generate an unrivalled low noise and distortion-free surface.

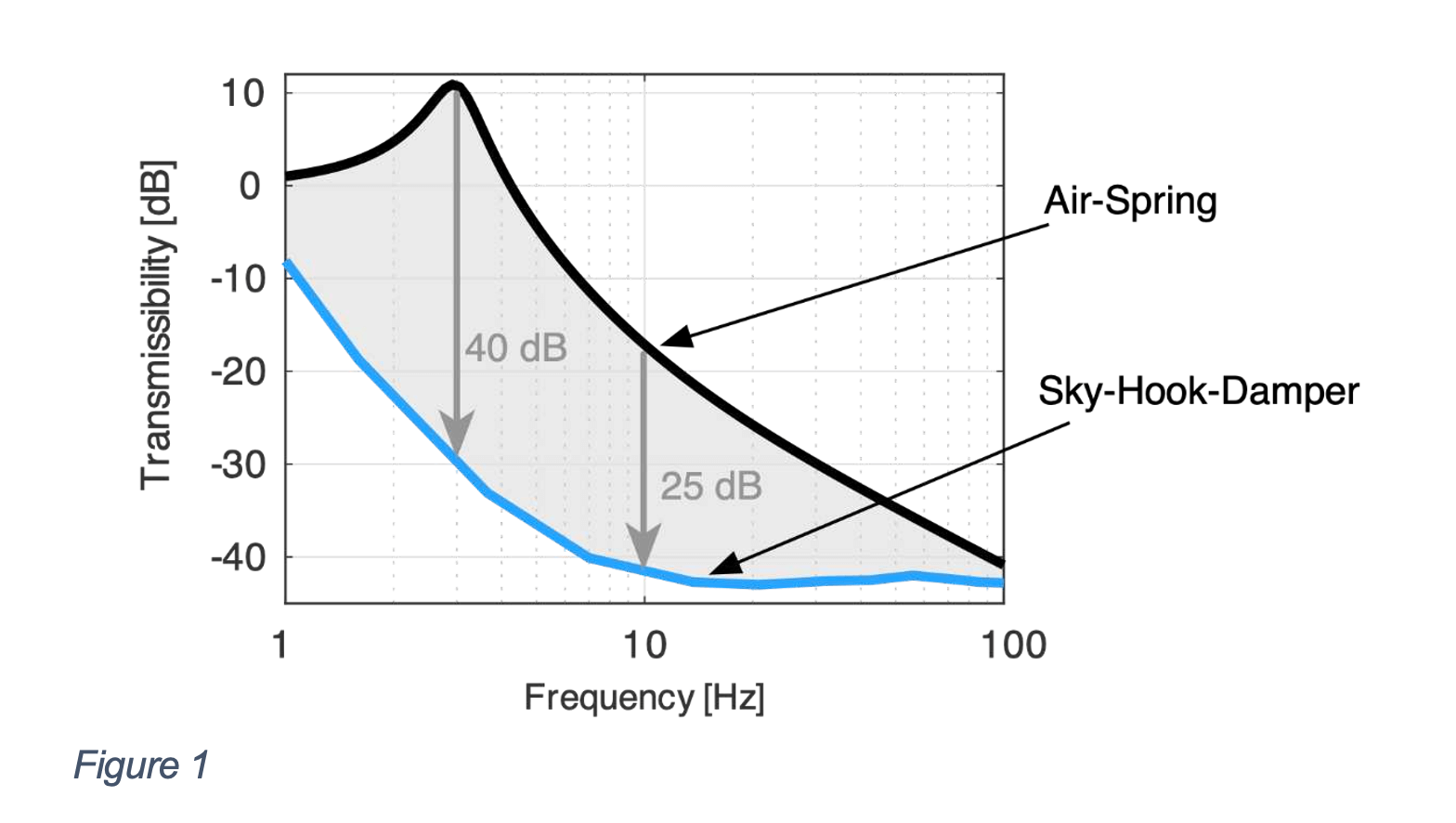

This sophisticated mechatronic system is based on Sky-Hook-Damping isolates disturbances already below 1 Hz and reduces them to less than 1% (-40 dB) at frequencies of 10 Hz and above. Such a performanceis far superior to any other isolation (figure 1). This figure shows the comparison of the active isolation system – Sky-Hook-Damper and a high-performance Air Spring. Especially at the critical frequencies around the resonance, the active isolation has a performance which is up to 100 times better. At 10 Hz it is still about 17 times stronger isolated than with an Air Spring. Other dampers like rubber mounts are on a much lowerperformance level and not shown in this comparison.

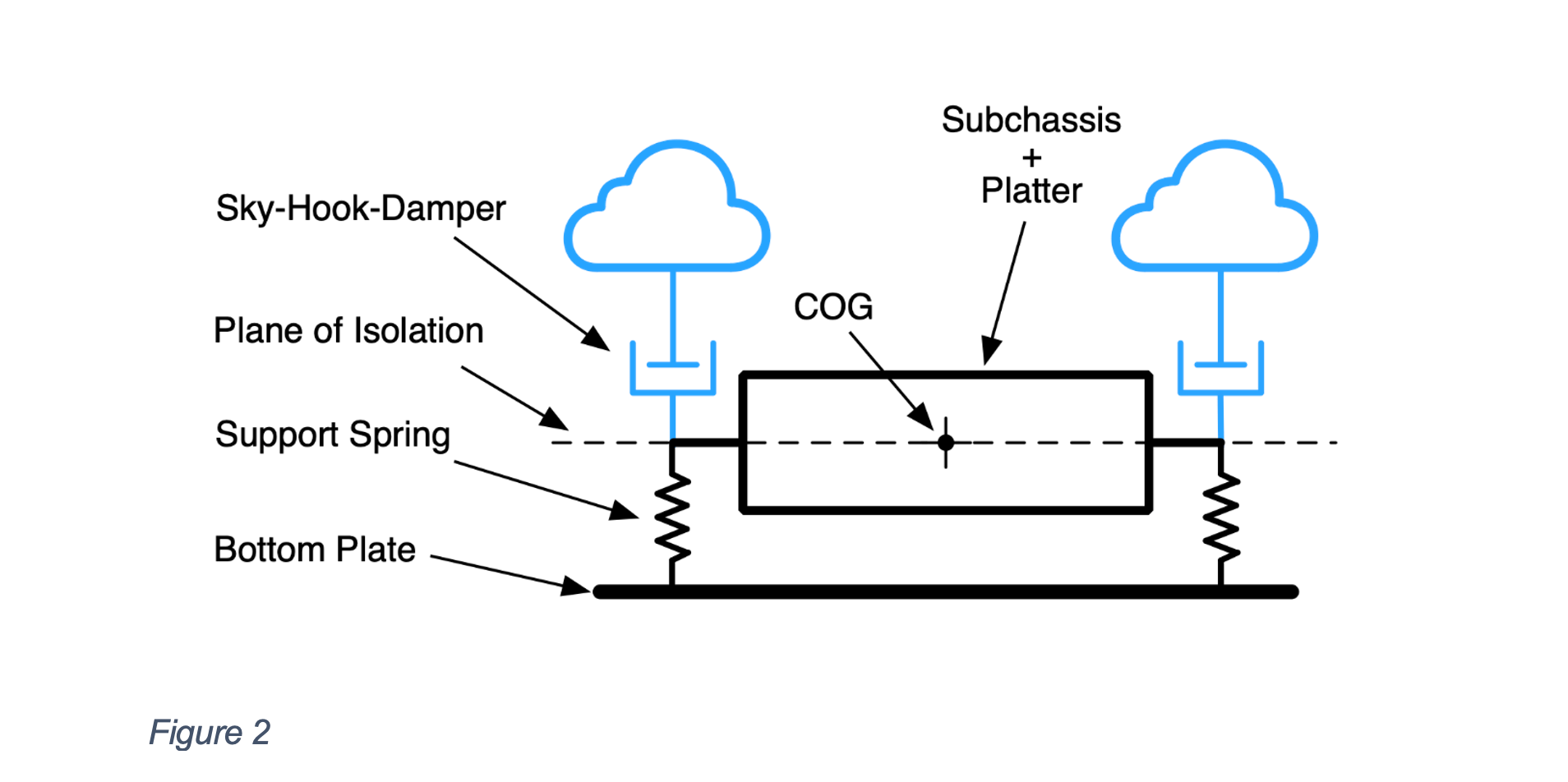

The overall system is designed in a way that the center of gravity (COG) is close to the plane of isolation. In this way, the coupling of horizontal vibrations and tilting motions are greatly reduced (figure 2). Furthermore, the chassis itself is made non-resonant by its layered structure of highly damped materials.

The effect goes far beyone the simple elimination of foot-fall vibrations. In fact even tiny vibrations in the range of a nanometer down to a picometer are still efficiently isolated, due to the contact-less actuators. The system also follows music with high dynamics between quiet and loud sequences extremely quickly, since the active control forces stabilize the system and lead to an instantaneous settling time of the isolation system. An adaptive levelling system, which keeps the turntable precisely levelled within 20 micro meter completes the active isolation system.

The other fundamental part of every turntable is the drive unit. The ultimate goal is to perfect and establish a constant rotation speed of the platter. This concerns both the absolute speed and the modulations of the speed around the mean value also called wow and flutter.

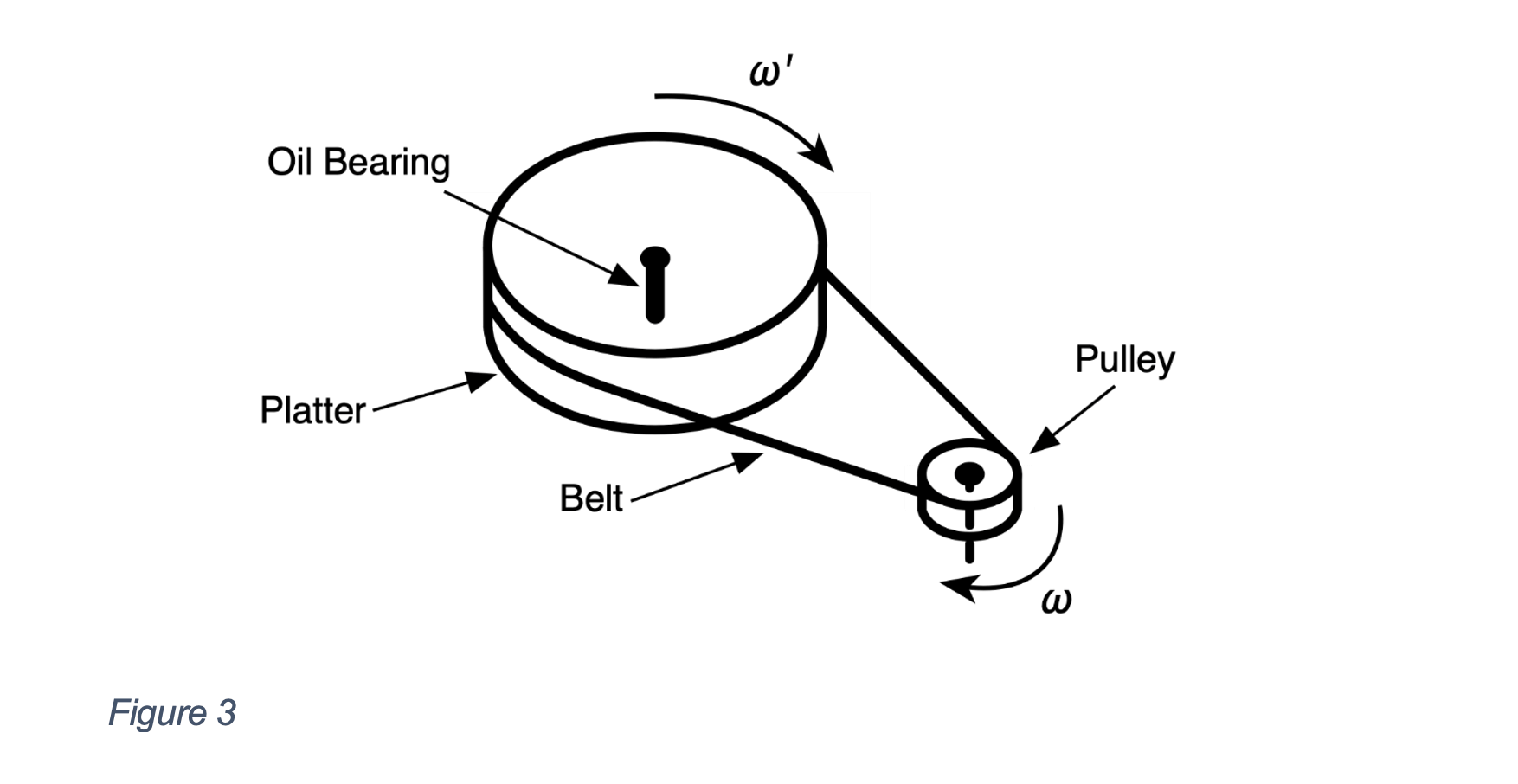

The Thorens New Reference features a high-quality German-made 3-phase synchronous motor, which is driven by three all linear power amplifiers with 120° shifted sine signals. The motor torque is transmitted to the platter by a belt (figure 3). The hydrodynamic bearing is optimized by use of lubrication theory equations. In this context, the Sommerfeld-number is used which describes the thickness of the lubrication film and the diameter of the bearing. This number is named after German physicist Arnold Sommerfeld, who conducted fundamental research in the field of hydrodynamics. A small Sommerfeld-number means the bearing is centered already at very low rotation speeds, which minimizes the wear and ensures minimum out of center errors like eccentricity and whirl. The hydrodynamic bearing is made and hand-finished in Germany.

Unlike Direct Drive systems, the turntable platter is isolated from the drive motor because of the elastic belt. The high inertia of the platter is therefore efficiently utilized and helps to passively remain a constant velocity of the platter. Moreover, any fluctuations from the motor are strongly suppressed by the platter/belt second order low-pass characteristics.

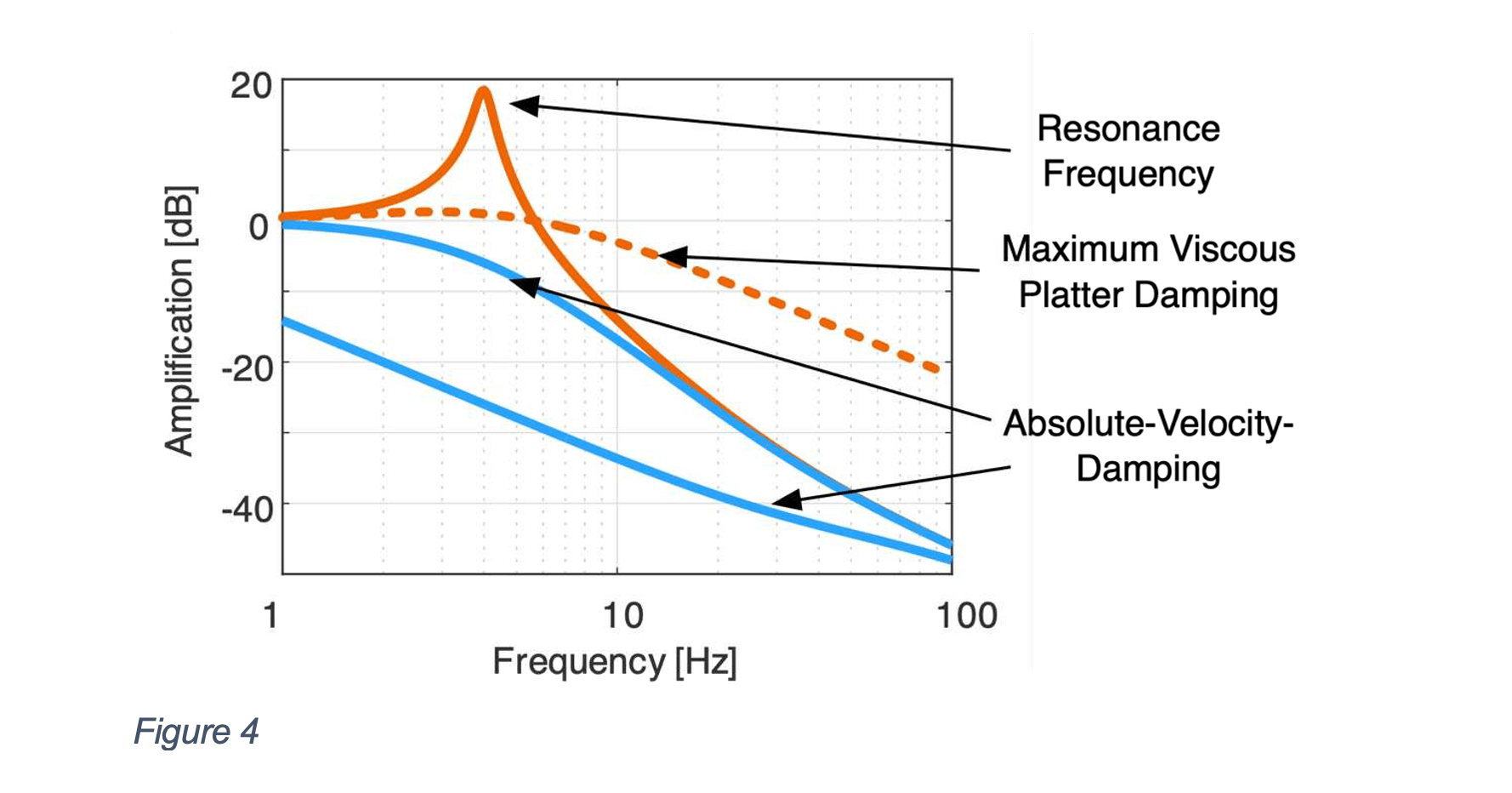

A common disadvantage of belt-driven systems is the potential resonance of the platter, which is observed aswow and flutter. The rotational inertia of the platter forms together with the elasticity of the belt an oscillatory system. The resonance frequency is typically about 4 Hz, but depends on the actual parameter values of the system.

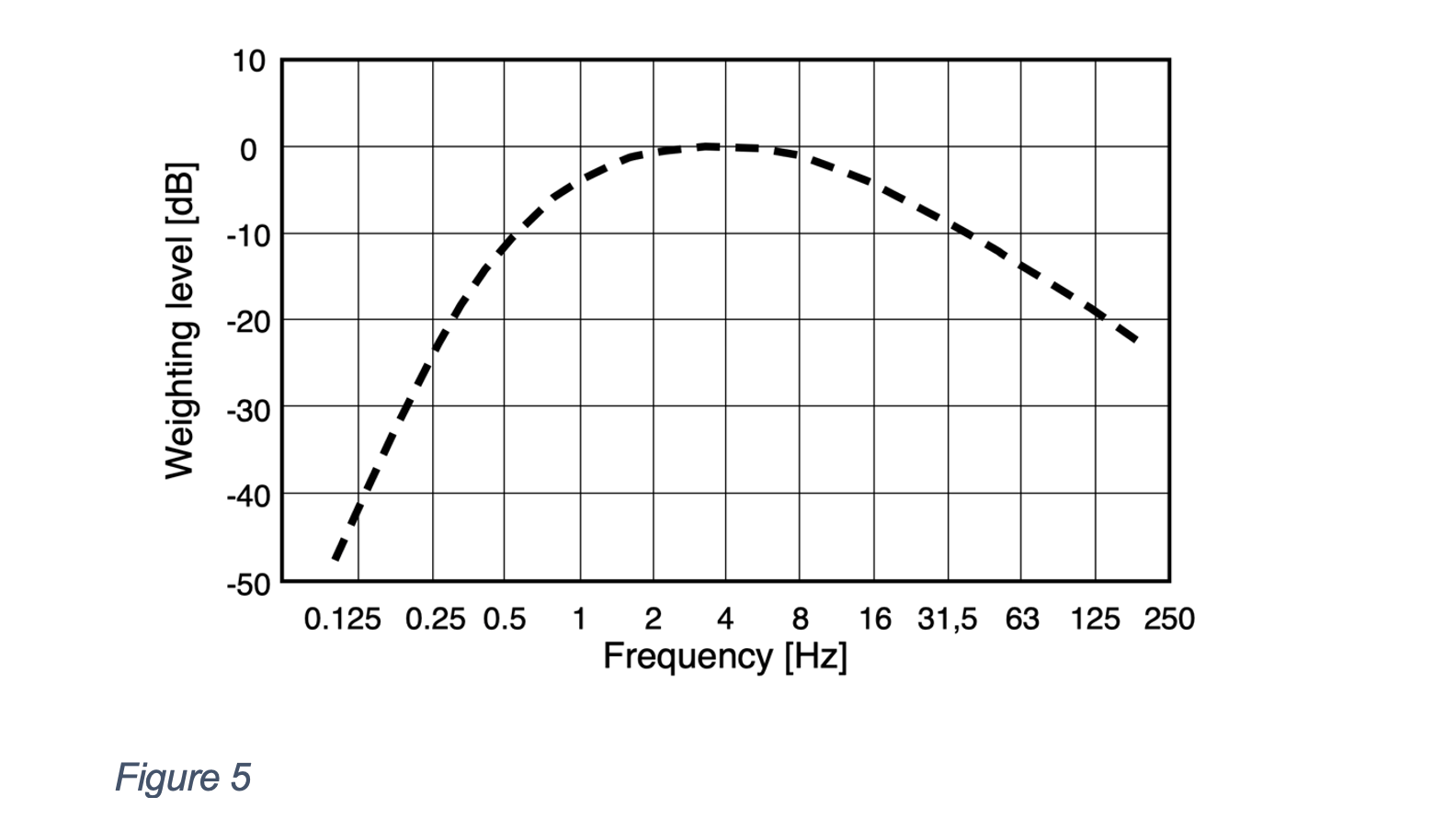

The orange graph in figure 4 shows a peak around 4 Hz, where all disturbances are strongly amplified. This means that the rotation speed of the platter is no longer constant but modulated with 4 Hz around the mean velocity. This effect is known as wow and is undesirable, especially sincethe human ear is most sensitive to this frequency range.

Figure 5 displays the weighting curve as described in DIN 45507 or IEC 386. The maximum of this weighing unfavorably coincides with the typical resonance of the platter / bearing system. Vibrations of the platter are excited mainly by the friction in the platter bearing, by a not perfectly circular platter, and by irregularities of the belt and slip between the belt and platter, which is necessary to transmit the torque from the motor. The orange graph sharply drops off for higher infrequencies. This is the desired effect of platter inertia. The rotation speed calculation of the platter is based on two ultra-high precision quartz oscillators with a long term stability of max 3 ppm over 20 years allowing for a safety cross check and reliable speed control over the lifetime of the New Reference.

The Thorens New Reference can be equipped with up to 3 tonearm bases and can accommodate tonearms of 9″, 10″, and 12″ inches. In addition to the newly developed TP160 cutting bearing tonearm with a length of 12″ inches and continuous silver cabling, the Thiele TA01 tonearm is also used.

The complex kinematics of the Thiele TA01 combines the precise and rigid guidance of a pivoted tonearm with the advantages of a tangential tonearm. This design guides the cartridge with a maximum tracking error angle of 0.036 degrees across the record. The tonearm tube is double-walled and filled with a 2-component gel for optimal damping. The result of this design is a unique spatial resolution, extreme detail, and perfect tonality.

Orders for the Thorens New Reference turntable can be accommodated through Erikson Consumer Home Division.