Erikson Home has announced that British loudspeaker manufacturer Mission has resurrected a classic speaker from its formative years, the iconic Mission 770, re-engineering the design to fuse vintage style with modern-day performance. The 770 will be manufactured in the UK.

Mission is one of Britain’s best-loved loudspeaker brands, established on 07/07/1977 by the late Farad Azima (who was famously fond of the number seven). The following year, Mission launched a speaker that rocketed the company to the forefront of the burgeoning British hi-fi scene – the highly influential Mission 770.

44 years since the original 770 made its debut, Mission is bringing back the 770 – re-engineered to reap the benefits of modern techniques and technologies whilst invoking the spirit of the original in terms of technical ethos, look and sound.

The appeal of the Mission 770 was always the way it sounded. That might seem obvious, but it was born in a time when subjective evaluation through listening tests was secondary to technical specifications – both in terms of how products were designed and how they were reviewed. By the numbers, the original 770 did not appear especially radical, despite its distinctive white baffle and clever engineering. But crucially, its sound was perfected over hundreds of hours of listening tests with input from budding industry luminaries such as Philip Swift and Derek Scotland (soon to be founders of Audiolab), and magazine editors such as Paul Benson of Hi-Fi Answers and John Atkinson of Hi-Fi News. This gave it an edge over the competition and a reputation for exemplary sound was quickly earned.

The project was a labour of love for Farad Azima. His intention was to deliver the BBC-influenced midrange accuracy and transparency of a speaker like the Spendor BC1 while also achieving tighter bass and a more propulsive and engaging sound. It was a breath of fresh air that put the music first and gave definition to the term ‘musicality’. This was the essence of its success.

The project’s design and engineering team was led by Peter Comeau, Mission’s current Director of Acoustic Design. Peter was a young reviewer for Hi-Fi Answers when the original 770 launched and well remembers its impact (he subsequently co-founded loudspeaker maker Heybrook in 1979). For Peter, the new Mission 770 is a labour of love; just as it was for Farad Azima all those years ago.

When Peter revisited the original speaker at the start of the project, he confirmed two key elements were fundamental to its highly musical performance. First, the polypropylene cone – claimed to be unique in a consumer product at the time – and second, the impressive resonance control of the cabinet. Naturally, these elements also became the cornerstone of the re-engineered design, yet every part has been improved including the drive units, the crossover and the cabinet – bringing the design thoroughly up to date whilst capturing the musical spirt that was so refreshing when the original speaker arrived on the scene.

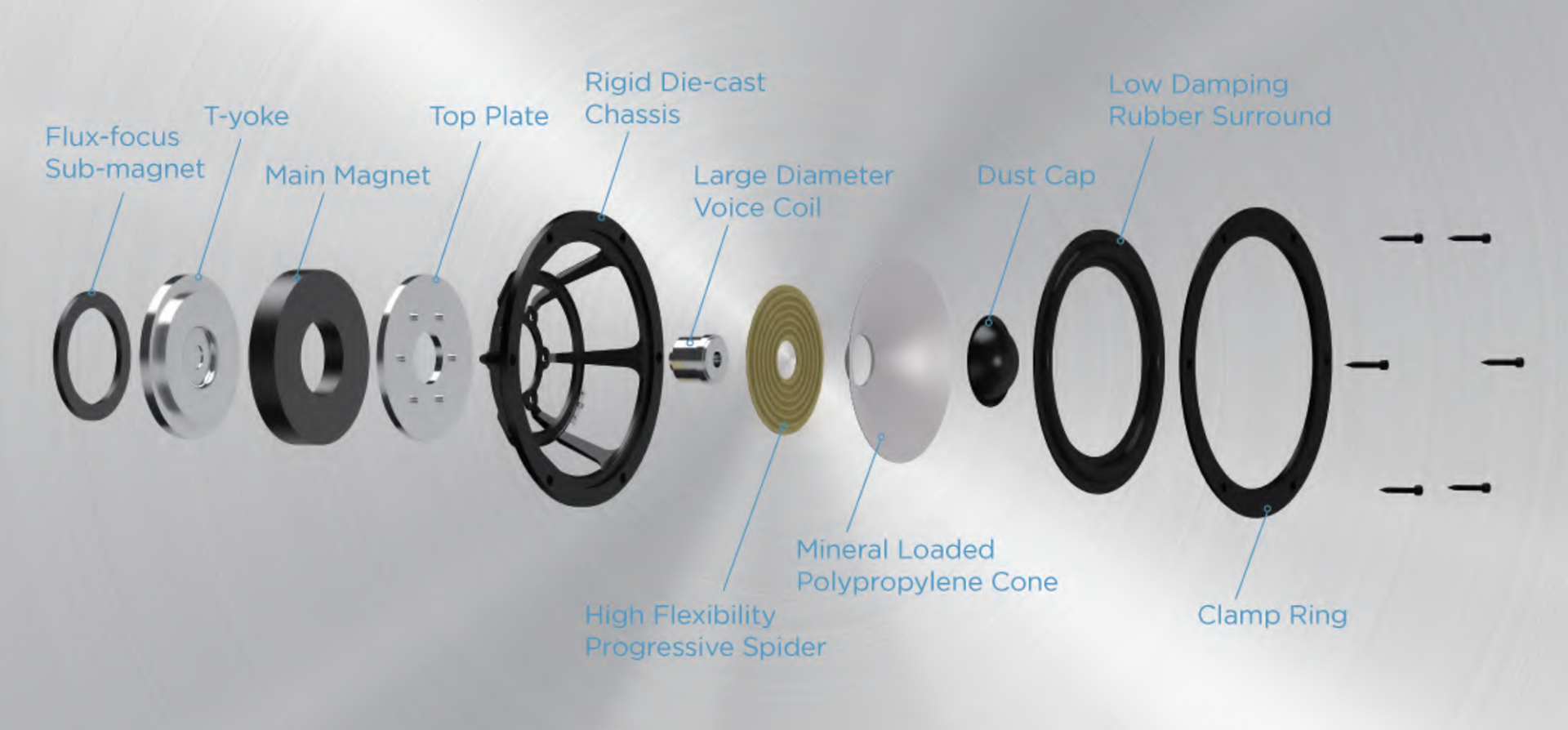

A new 20cm polypropylene mid/bass driver was developed for the re-engineered 770, mimicking the extended response and low coloration of the original, while upgrading the motor system to take account of modern power handling and dynamic requirements. Like the original, the driver is built onto a die-cast chassis with large rear “windows” to reduce early reflections back through the cone. Special care has been taken to marry a low-density nitrile surround to the cone, to match its impedance and reduce reflections from the cone edge.

The new polypropylene cone is loaded with minerals to make it stiffer than the original, yielding fast, tight bass that enables the listener to hear exactly how bass instruments are being played says Mission. This is balanced by tuning the cabinet and reflex port to a very low frequency, avoiding the “one note bass” that is typical of a lot of bass reflex systems. In addition, the port is strongly flared at both inlet and outlet to smooth airflow and eradicate distortion. Bass extends powerfully and cleanly to below 30Hz in room, which is remarkable for this size of speaker.

In the original 770 design, Farad Azima focused on the midrange performance, which was always the strength of hi-fi reproduction from vinyl records. For today’s digital sources and superior turntables, the Mission 770 has a completely redesigned mid/bass driver assembly with a new-formulation for the polypropylene cone to deliver better performance. The new 770’s treble unit uses a lightweight, damped microfibre dome with an ultra-smooth response, backed by a damped rear chamber that pushes the fundamental resonance well below the crossover region. The quality of this 28mm dome marries perfectly with the mid/bass driver to ensure evenness of character throughout the range of the whole speaker.

The drivers and crossover are housed in a real-wood veneered cabinet, measuring 59x30x30cm (HxWxD), with a white laminated front baffle echoing the style that made the Mission 770 a stand-out hi-fi product in the 1970s and ’80s. Beneath the rich, rosy-tinged walnut or black veneers lies a further technological advancement. While the original 770 reduced midrange coloration using the BBC-influenced technique of a thin-wall cabinet damped by mass loading with bitumen pads, the new 770 features a twin-wall sandwich of high-density MDF and particle board bonded by a layer of 28mm microfibre. This results in a cabinet with panel resonance well below audibility, allowing the drive units to do their job unsullied by cabinet coloration at all frequencies.

Peter Comeau is justly proud of what he and Mission’s acoustic engineering team have achieved. Speaking about the launch, Peter said, “to repeat the original 770 brochure’s claims of ‘staggering bass definition and response; lack of coloration; uncanny imaging; information retrieval; transient attack; depth and perspective; accuracy and linearity; speed and dynamic range’ is only to hint at the true capabilities of the new 770. Instead, we prefer to focus on its uncanny ability to reveal the true depth, emotion, and drama of whatever music you care to feed to it. A much-loved British hi-fi classic has been emphatically reborn.”

The new Mission 770 is not only designed and engineered in the UK; it is also manufactured at the Mission facilities in Huntingdon, Cambridgeshire. A 9,000 square foot production facility has been added to the existing 25,000 square foot building in Huntingdon to include a new anechoic chamber, lab and manufacturing space.

Like most British audio brands, especially those operating at more affordable price points, manufacturing of Mission speakers was moved to Asia (to Mission’s parent IAG’s purpose-built factory) many years ago, essential in order to maintain retail prices at the level the market demanded, while design functions such as R&D and industrial design remained in the Huntingdon. IAG’s new Made in the UK initiative has been devised to enable the manufacture of specific products to be brought back to the UK without skyrocketing costs integration between the drive units, so that the speaker behaves as a single, coherent music-making system.

‘Heritage’ products are the focus of this initiative; speakers that are steeped in British audio history, where ‘Made in the UK’ adds to the sense of historical authenticity. The new Mission 770 is the first to benefit.

UK Manufacturing of the new Mission 770 is now under way, in strictly limited quantities. The first pairs will be available to purchase from Erikson-Home in Canada from the end of May, in a choice of walnut or black wood veneers priced at $6500 CAD/pr including dedicated stainless-steel floor stands also custom made in the UK.